Rapid Prototyping for Medical Devices

We design and build working prototypes quickly - mechanical, electronics and firmware - with the rigs and measurements you need to make decisions.

What you get (fast)

A device you can handle and test. Not a render.

Bench data. Force, flow, dose, repeatability – whatever answers the risky question first.

Tight build-test-learn loops. Days, not months.

Files you can grow. CAD where created, a simple BOM, firmware stubs, notes and videos.

We keep paperwork light but aligned to the standards you’ll meet later (ISO 13485, ISO 14971, IEC 62366).

What we prototype

Mechanical

Enclosures, mechanisms and linkages, drive systems, soft-tooling samples and fit/finish parts.

Form & ergonomics.

Handheld form models, grips, control layouts, access for assembly/cleaning; quick formative handling checks.

Materials & build

Material trials (sterilisable/skin-contact), tolerancing tests, fastening/joining approaches, seals and wear points.

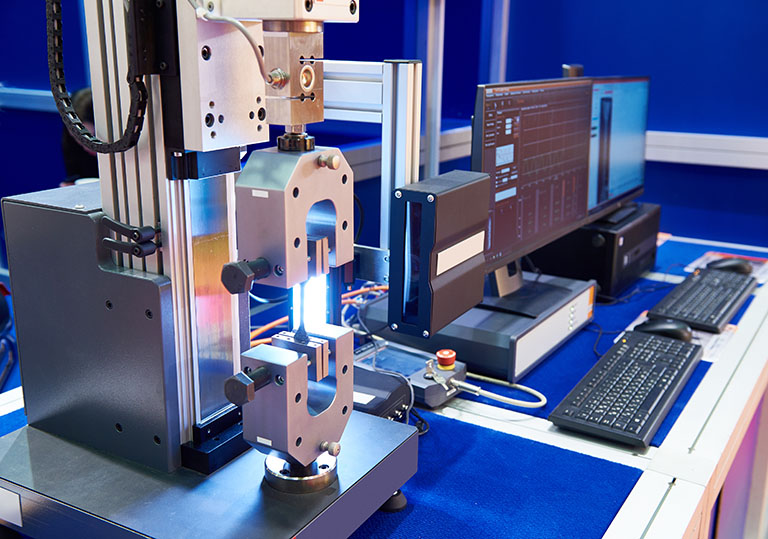

Rigs & fixtures

Strain/force/flow rigs, motion fixtures, endurance jigs and simple data capture to measure what matters.

In-house prototyping

We run FDM and SLA 3D printers in the studio, plus light bench fabrication, so we can print, fit and test the same day.

- FDM: PLA, PETG, ABS/ASA, PA (nylon), TPU (flex).

- SLA: tough/ABS-like, clear and heat-resistant resins; fine features and smooth surfaces.

- Turnaround: most parts same-day/overnight; quick reprints for iterations.

- Finishing: threaded heat-set inserts, light machining, bonding, sanding; simple coatings where useful.

- When we outsource: metal CNC or production-like finishes, they are handled via our partners as needed.

Prototypes, rigs, and early evidence

Functioning prototype (mechanical/electrical) you can demo

Bench rig with measured performance

Minimal firmware + logs (clear and tidy)

CAD where applicable, simple BOM, test notes and videos

FAQs

Yes. You own the hardware and outputs created – CAD where applicable, a simple BOM, code stubs, data and notes.

Yes for early boards and firmware stubs.

Then we’ve saved you time and budget. We’ll show options and where to pivot.

It’s early-stage work. We keep it aligned so it won’t fight you later, but full design history/verification comes after feasibility.

As standard, we work under NDA, and everything we produce is client-owned.