Concept Feasibility & De-Risking for Medical Devices

In 1–2 weeks, we pressure-test the idea, build what’s needed to learn fast, and give you a clear “go/no-go” with timelines, risks and next steps.

What you get in 1-2 weeks

Clarity on viability. Constraints, critical assumptions and a measured path that fits UK/EU reality.

Evidence from quick builds. The minimum rigs, models or code to answer the risky questions first.

Early risk snapshot (ISO 14971). Top hazards, mitigations to explore, and what to park.

A decision. Go / pivot / stop – with an honest cost-and-time view.

We keep paperwork light but aligned to the standards you’ll meet later (ISO 13485, ISO 14971, IEC 62366).

How the sprint works

Kickoff & hypotheses

We frame the problem, success criteria and unknowns. Agree what we must learn first and how we’ll measure it.

Quick design & build

CAD and form studies where useful; simple benches/fixtures; breadboard/PCB if the question is electronic/software.

Test & iterate

Exercise the rig, record data/video, adjust once or twice. Kill ideas that don’t hold up. Keep the ones that do.

Decision & roadmap

We present results, risk snapshot, options, costs and a right-sized next step (prototype, usability, or straight into DfV).

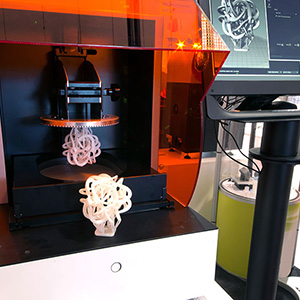

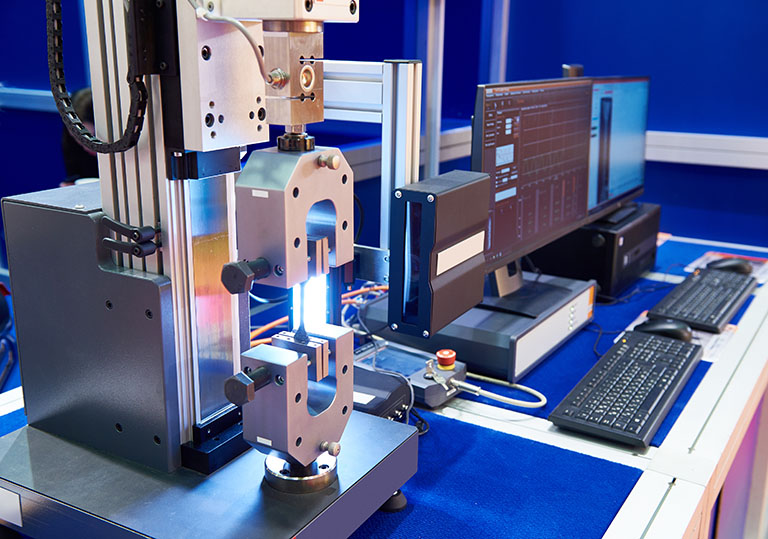

Fast prototypes and test rigs

- Bench rigs & fixtures to isolate the key behaviour (mechanical, fluidic, electrical).

- Form models for early handling and user tasks (foam/CNC/printed).

- Simple electronics & logging to capture the signal that matters.

- Data sheets & notes that prove or disprove the risky assumption.

What you leave with

- Feasibility brief (scope, questions, constraints, pass/fail criteria)

- Results pack (photos/video, key plots, what worked, what didn’t)

- Risk snapshot (ISO 14971) – top hazards, mitigations to explore next

- Next-step roadmap – 2-3 options with time & budget bands

- All files we created – CAD where applicable, simple BOM, test notes

Why do this now?

Because every week spent polishing the wrong design is expensive. Early bench evidence and formative handling stop waste and point you at a build that will actually pass verification later.

FAQs

Usually inside a week. If you have materials/components ready, we can move faster.

A problem statement, constraints and any prior work. We’ll ask for 2-3 success criteria we can actually measure.

Yes. You own all outputs created during the sprint (CAD where created, code stubs, data, notes).

It’s early-stage work. We keep it aligned to ISO 13485/14971/62366 so you don’t paint yourself into a corner, but full files come later.

Good. That’s a cheap win. We’ll show you alternatives or where to pivot.