Proof-of-Concept Builds & Bench Test Rigs

For founders/CTOs who need a clear yes/no backed by real numbers - fast

When a PoC is the right move

- You’re not sure the physics will cooperate (force, flow, dose, repeatability).

- You need evidence for a go/pivot/stop decision or investor meeting.

- A full prototype is overkill – one question must be answered first.

- Off-the-shelf kit won’t replicate your constraints.

Outcome: one question answered with real numbers, not a spreadsheet guess.

What we build

Proof-of-concept assemblies

The smallest build that demonstrates the mechanism/transfer/actuation

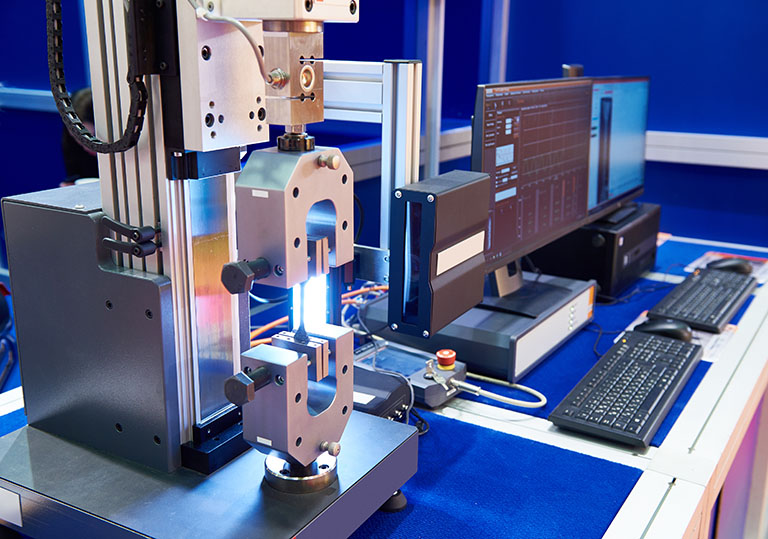

Custom bench rigs

Strain/force/pressure/flow rigs, motion fixtures, endurance jigs, controlled temp/humidity when needed.

Instrumentation & logging

Load cells, encoders, pressure/flow sensors, simple DAQ; minimal firmware for data capture.

Test methods

Pass/fail criteria, sample plan, how to repeat it next week without us.

The PoC path

Define the question

What must we learn first? Set constraints and success criteria.

Design the minimum

The smallest build that can answer it.

Build the PoC & rig

Simple, swappable parts and a clean bench setup.

Run the tests

Capture the signals that matter; tweak once if needed.

Decide with data

Keep, change or stop - plus the next step.

What we need

- The single question you must answer, plus constraints

- Any prior work, limits, or must-not-fails

- A rough success band (e.g., “≥ X N within Y mm”, “≤ Z% CV”)

Typical measurements

- Force & torque: breakaway, actuation, hold, repeatability.

- Flow & pressure: steady-state, transients, leakage, back-pressure.

- Position & motion: displacement, velocity profiles, backlash, drift.

- Dose & delivery: accuracy, precision, CV, time-to-dose.

- Endurance: cycles to change/failure, wear points, creep.

We size the rig to the question – clean, repeatable, and easy to re-run.

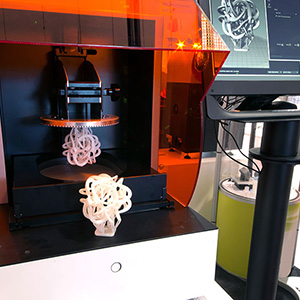

In-house capability

- FDM & SLA printing for same-day parts; light machining/laser.

- Simple electronics assembly and firmware for logging.

- Quick reprints and part swaps between runs.

- We outsource only when it truly saves time (e.g., metal CNC).

Deliverables

- PoC assembly and bench rig (or drawings to reproduce).

- Results pack: plots, photos, short video, raw data.

- Test method (v1): setup, calibration notes, pass/fail, repeat steps.

- Decision summary: keep / change / stop, with next-step options.

FAQs

Yes – if we’ve built a dedicated fixture for your question, it’s yours. If it’s a lab rig we reuse, you’ll get drawings/specs to reproduce it.

It’s early-stage. We log what matters and draft a simple method so you can repeat it. Full verification comes after the design stabilises.

Yes – raw data, plots and a short video of the setup and runs.

That’s a good outcome. We’ll propose alternates (geometry/material/drive) or where to stop.

As standard, everything we create for the PoC is client-owned.